IMCE

Institute for Materials Chemistry and Engineering, Kyushu University

九州大学

先導物質化学研究所

LAST UPDATE 2017/02/25

-

研究者氏名

Researcher Name林潤一郎 Jun-ichiro HAYASHI

教授 Professor -

所属

Affiliation九州大学 先導物質化学研究所

先端素子材料部門・ミクロプロセス制御分野

Institute for Materials Chemistry and Engineering, Kyushu University

Laboratory of Microprocess Control, Division of Advanced Device Materials -

研究キーワード

Research Keywords

Low rank carbon resources such as lignite and biomass

Thermochemical and thermocatalytic conversion

Syngas and chemicals

Carbon materials

Reaction and reactor design

Local energy/material conversion

- 研究テーマ

Research Subject -

低品位炭素資源のシーケンシャル熱化学・触媒化学変換プロセス

Sequential thermochemical and catalytic conversion processes

研究の背景 Background of the Research

褐炭などの低品位炭は,それが持つ特有の物性(負の物性)によって有効な利用が進んでいませんが,わが国にとっては資源安全保障の観点から極めて重要な資源であり,物性を「正の物性」として活用できる変換技術が求められます。バイオマスは,燃料としては褐炭と類似の物性が少なくない一方,化学原料として高いポテンシャルを有する貴重な国産資源です。

Low rank coals such as lignites and brown coals, which are important carbon resources form a viewpoint of energy security, have particular properties with negative impacts on conventional conversion technology. Effective use of those resources has been realized within a limited range, but should be done by taking most advantage of their properties. While biomass has properties (as a fuel) similar to those of lignites, it has a quite high potential as feedstock of chemicals and materials. In addition, it is a domestic carbon resource, which is essential in future evolution of primary industries.

研究の目標 Research Objective

物理/化学的な改質,熱分解,ガス化,炭化,溶剤抽出(反応溶解),触媒変換等のプロセスの開発,これらに逐次並列的組み合わせと最適化による「付加価値連鎖型」の褐炭,バイオマスの変換シーケンス・ネットワークの構築,コプロダクション(同時のエネルギー変換,ケミカルズ・素材等製造)を最終目標とする反応工学的研究を展開しています。

Experimental and numerical studies have been in continuation on physicochemical upgrading, and catalytic, thermal and electrochemical conversions (pyrolysis, gasification, carbonization, etc.) of lignite and biomass based on chemical reaction engineering. The ultimate goal of those studies is proposal/demonstration of ‘high value added’ coproduction processes and their sequences/networks.

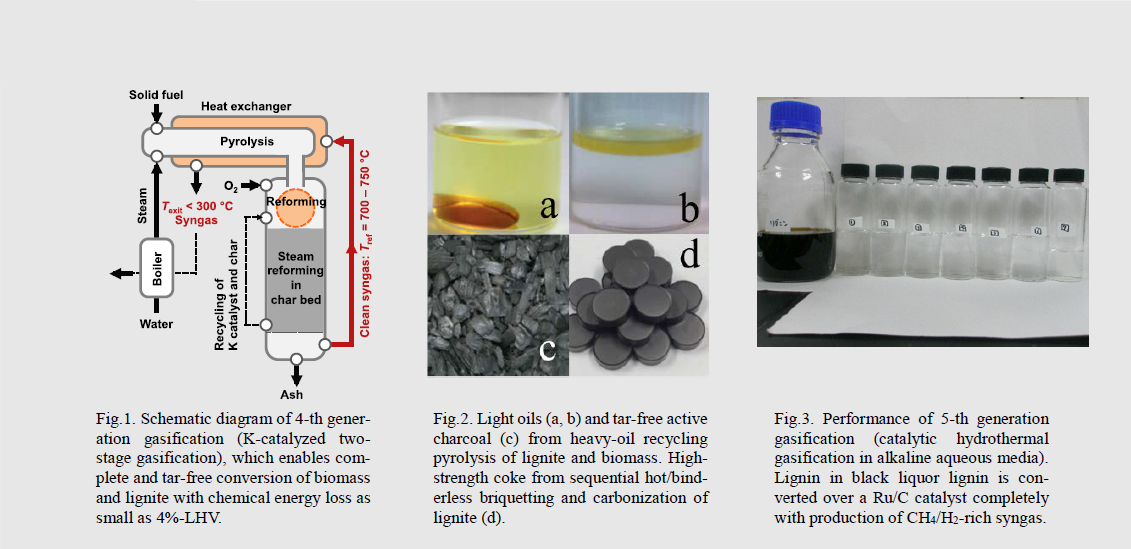

研究図Figures

論文発表 / Publications

Low temperature Gasification of Biomass and Lignite: Consideration of Key Thermochemical Phenomena, Rearrangement of Reactions, and Reactor Configuration. Jun-ichiro Hayashi, Shinji Kudo, Hyun-Seok Kim, Koyo Norinaga, Koichi Matsuoka, Sou Hosokai. Energy & Fuels 2014, 28, 4–21.

研究者連絡先 / HP

- Junichiro_hayashi

cm.kyushu-u.ac.jp

cm.kyushu-u.ac.jp - http://carbonres.cm.kyushu-u.ac.jp/